has a green soul

An innovative and patented system for colouring polymers

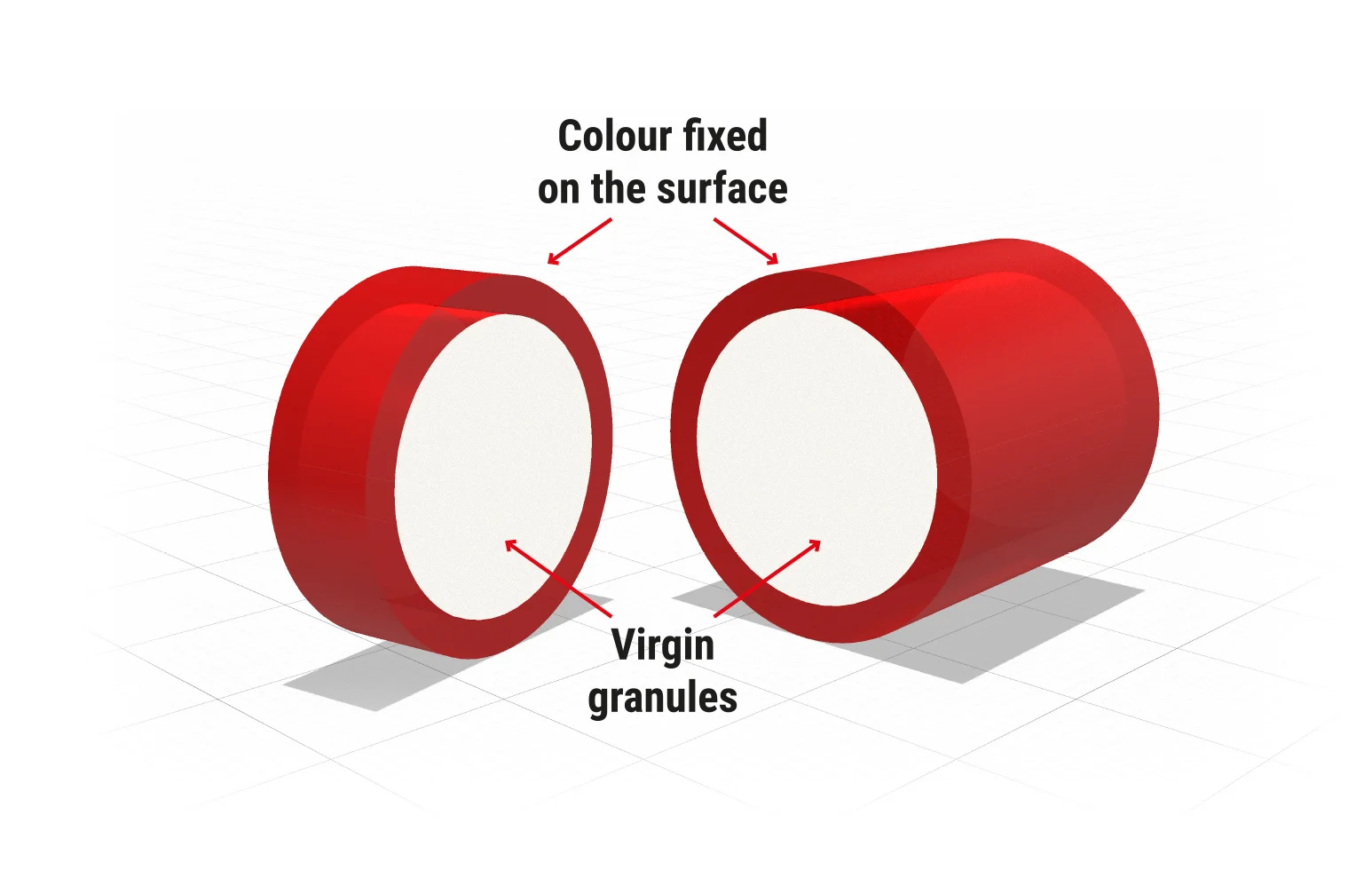

At first glance the Vesticolor® granules seem like the ones coloured through extrusion but they are neutral inside.

Each granule is covered by a lay of colour fixed on the surface. During moulding the press melts the granule making the produced item full-coloured and without imperfections!

A sustainable production

Thanks to their clean productive process, the Vesticolor granules provide an advantage in terms of sustainability: Vesticolor technology grants a high energy saving and an optimal carbon footprint.

Also the customer production get advantages for this because of a really good LCA.

Sustainability index

We got the ISCC + certifications as proof of our productive process sustainability, according to the principle of Mass Balance.

Process for recycled plastic

Our peculiar patented technology allows us to produce coloured granules and powders from recycled plastics.

The opportunity, for a company, to recycle its own scrap materials gives a double advantage:

- the recycle of scraps avoiding

- the quality assurance of the final product

Global Warming Impact: Vesticolor compared to the Industrial Average

The following chart provides a comparison of the potential impact category on global warming. It compares the value calculated for Vesticolor’s patented activity with the impact of other companies’ processes in the same sector in Italy and Europe

| Impact categories | Unit | VESTICOLOR Productive process | Average impact on major processes in other companies |

|---|---|---|---|

| Total global warming | Kg CO2-eq | 0,04053 | 0,39764 |

Study by